Best-in-class food safety and quality system:

comprehensive quality control, from feed and egg to

finished product

Process & Safety

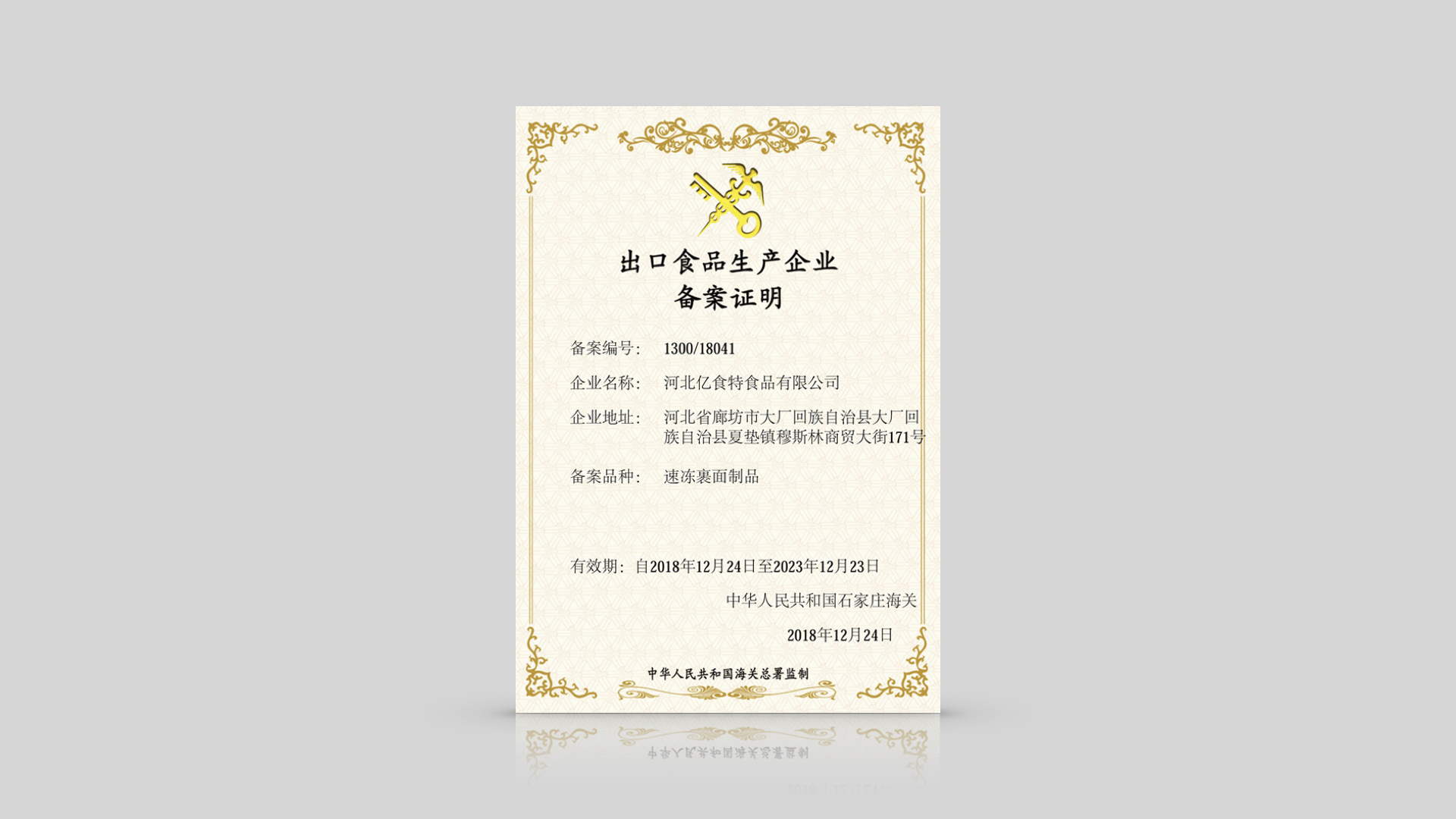

Certifications

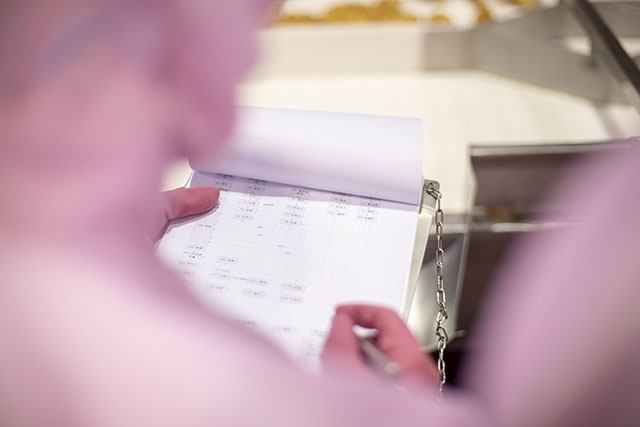

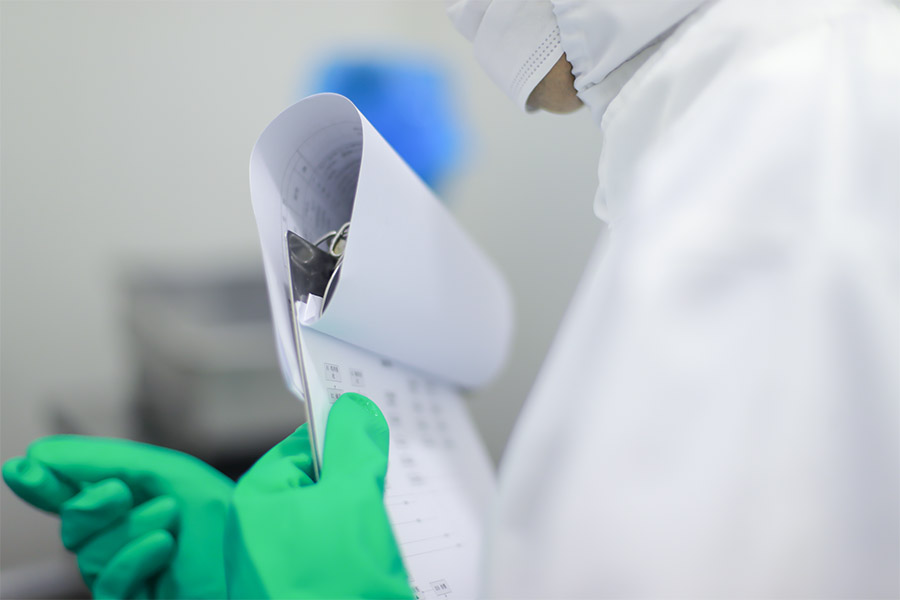

There are over 110 quality assurance steps before any product is shipped to our customers – and our professionally trained staff oversee each and every one of them. And we do it well: our operations have received multiple globally recognised quality management certificates, such as ISO 22000, HACCP, and FSSC 22000, as well as having been trained in Japan’s highest-level food safety and quality management standard, JFS-C.

Premium White Feather Birds

The chicken meat for our products is supplied from our own facility located in the green hills of Shandong Province. Otto & Sons Asia exclusively uses Premium White Feather Birds for its food products.

Vertical Integration

What makes us special is that Otto & Sons Asia’s chickens for Japan come from our fully owned vertically integrated operation: this allows us to secure full control from the breeder, layer, hatchery, and broiler farms, the feed mill, and the slaughterhouse, all the way to distribution, to make sure that our quality standards are met from the very beginning to the very end.

Feed Quality

We use an all-vegetarian diet for our chickens, balanced with amino acids and probiotics. The process starts with the preparation of this mix of grains and corn with different vitamins and minerals in our in-house feed mill. This ensures the health of the chickens and provides the most tender and juicy meat possible for our products. We also have our own on-site laboratory to ensure that no growth-promoting or preventive antibiotics enter the chickens via the feed.

Healthy Environment

The process continues with the environment we provide for our chickens, ideally suited to nurture them in a healthy and stress-free manner in their natural, 42-day growth cycle. Our chickens are raised without antibiotics defined by the World Health Organization (WHO) as Highest Priority Critically Important Antimicrobials (HPCIA) for human medicine. We guarantee the highest international standards – this means water and air filtering, controlled light and temperature, and space management from sustainable factory production up to further processing, including food safety testing, packaging and shipping.

Investing in the Best

The raw meat is transported to nearby Hebei Province, where we run our modern production facility and where our food products are made. We just invested RMB10,000,000 to further upgrade our production in May 2018 – a demonstration of our commitment to food safety and quality control.

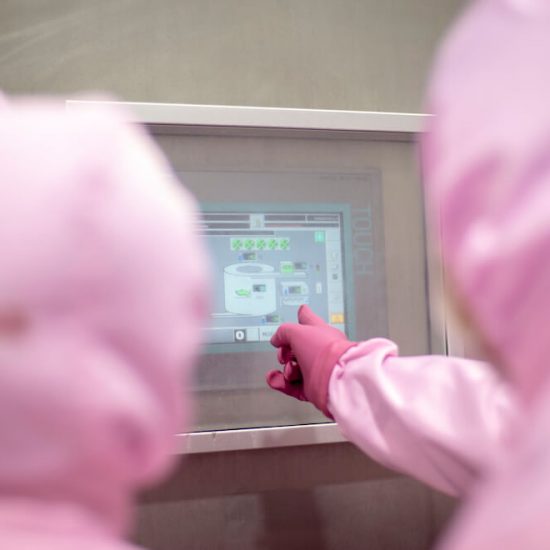

Leading-edge Machinery

In our Hebei plant we work only with leading-edge machinery imported from Japan, the EU and the U.S. to create our signature food products that are enjoyed by millions of people around the globe every day.

Our HPCIA antibiotics-free guarantee

Our chickens are raised without HPCIA (Highest Priority Critically Important Antimicrobials) for human medicine as recommended as best practice by the WHO.

This tackles the key issue of humans building up antibiotic resistance through food consumption. We exclusively use antibiotics for necessary therapeutic reasons to ensure the health of our chickens and animal welfare. Our operations strictly follow defined withdrawal period rules and our chickens are routinely checked to ensure there is no antibiotic residue in the chicken meat before shipping.

Safety

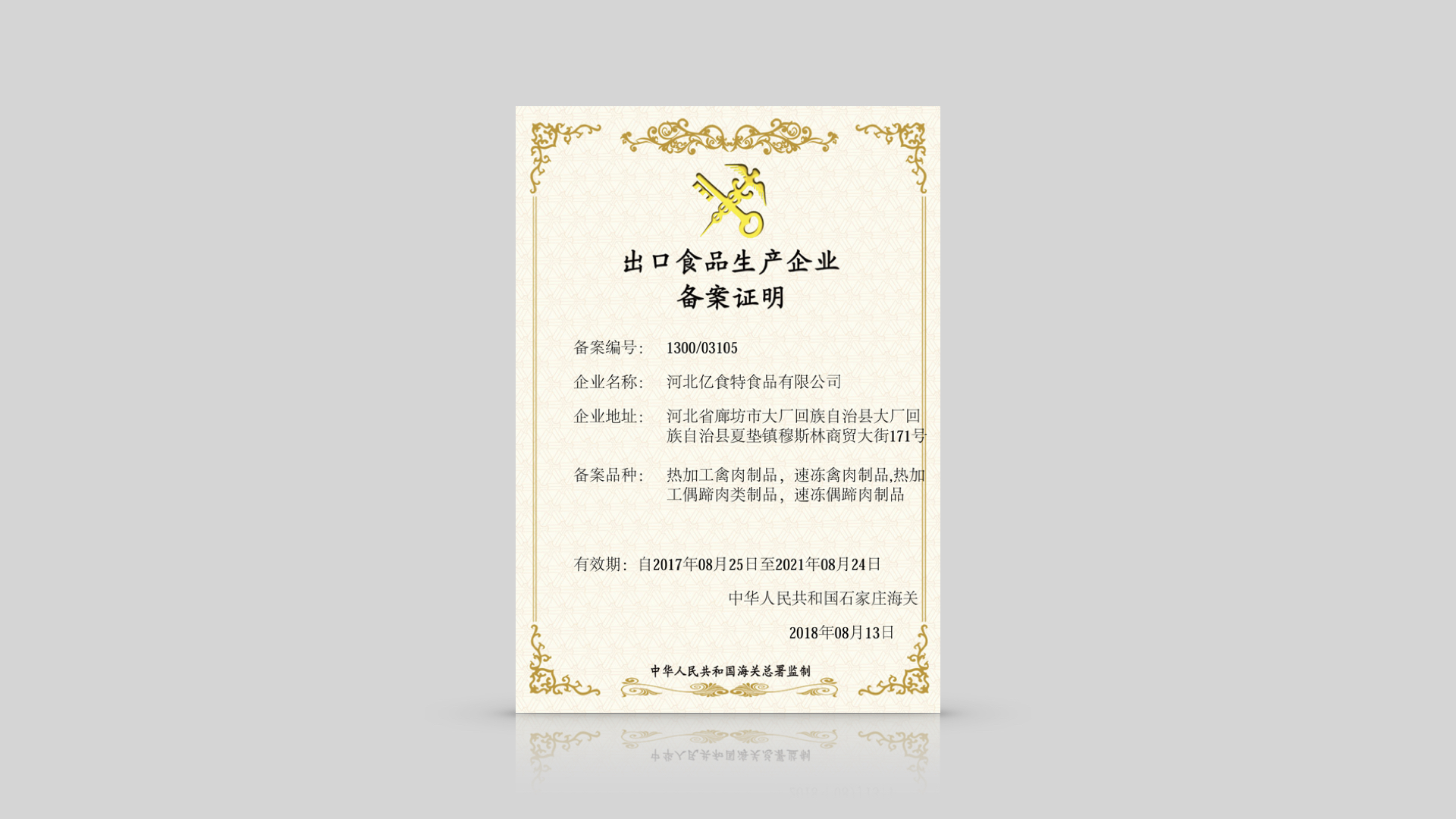

Otto & Sons is a globally recognised leader in food quality and safety management. Here are some key steps we take in our Hebei and Shandong operations to ensure the quality and safety of our products:

Global Standards

Our factories are state-of-the-art and certified with all leading global standards (HACCP, ISO 22000, BRC, and FSSC 22000). In addition, Otto & Sons Asia also follows the OSI Group’s Global Quality Expectation standards and food safety frameworks policies (such as the Listeria Environmental Monitoring Program and QA Equipment Sanitary Design). These uncompromising standards allow us to meet the strict exporting standards to Japan and the EU.

Traceability

Our tracking system allows every lot of chickens from Otto & Sons Asia to be traced from your table back to the farm, through the entire processing chain.

X-ray Checkpoints

We scan the incoming raw materials used to produce every package of our products for potential foreign objects, such as remaining bone fragments or metal shavings.

Metal Detectors

We scan every package of our finished products for potential metal objects.

Japanese Food Safety and Quality Standard Training

Our factory is inspected by Japanese quality assurance organisations and our quality and floor staff are trained to meet Japanese food safety and quality management standards.

Chicken farmhouse environment control designs

- Air control (check and control NH3 levels);

- Water filtration and treatment;

- Automated feeding, watering monitoring and control systems;

- Automated environmental (temperature & humidity) monitoring and control systems;

- Meticulous, supervised cleaning and disinfection practices before any personnel or vehicle can enter the production line or chicken farm to ensure biosecurity control;

- Backup power or emergency ventilation must be provided within 15 minutes when required;

- Lighting is adjusted to be as uniform as possible and exposure to light is conducted according to designated rules